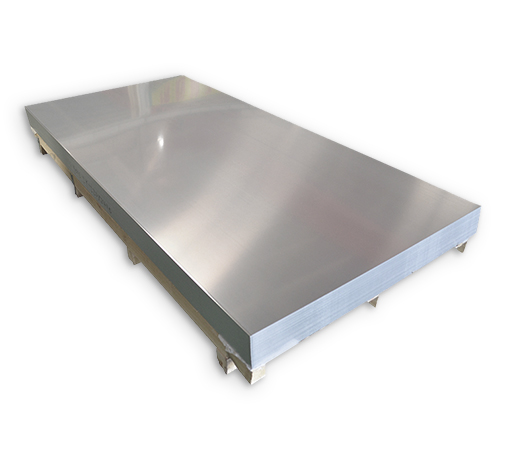

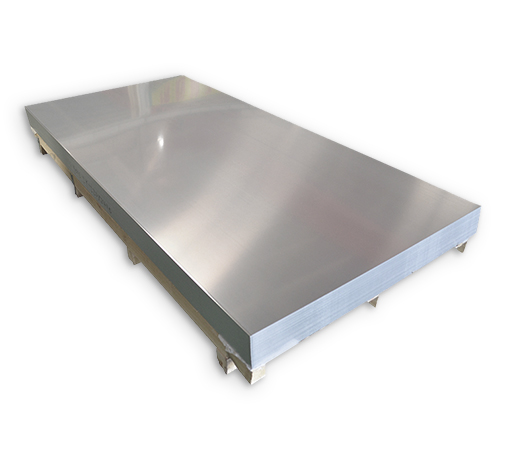

The surface is polished more than 400 meshes, has no milling, can be directly anodized and has no color difference, its oxidation effect is much better than the ordinary frosted aluminum plate

The surface is polished more than 400 meshes, has no milling, can be directly anodized and has no color difference, its oxidation effect is much better than the ordinary frosted aluminum plate

A special process has adopted to control the residual stress to a minimum, greatly reduce the generation of deformation, and greatly reduce the cost of machining

A special process has adopted to control the residual stress to a minimum, greatly reduce the generation of deformation, and greatly reduce the cost of machining

With high hardness and wear resistance, the number of uses is up to 20,000 times

With high hardness and wear resistance, the number of uses is up to 20,000 times

Features of 6 Series Aluminum Plate

The 6-series aluminum alloy is an aluminum alloy with magnesium and silicon as the main alloying elements and Mg2Si phase as the strengthening phase. The alloy has the advantages of medium strength, high corrosion resistance, no stress corrosion cracking tendency, good welding performance, unchanged corrosion performance in the welding zone, good formability and process performance. When the alloy contains copper, the strength of the alloy can be close to that of the 2-series aluminum alloy, and the process performance is better than that of the 2-series aluminum alloy, but the corrosion resistance is deteriorated, and the alloy has good forging properties. The most widely used 6-series alloys are 6061 and 6063 alloys, which have the best comprehensive properties. The main products are extruded profiles, which are the best extruded alloys. The alloys are widely used as building profiles.

Application of 6 Series Aluminum Plate

6005 Extruded profiles and pipes are used for structural parts requiring higher strength than 6063 alloy, such as ladders, TV antennas, etc.

6009 Auto Body Panel

6010 Automotive Body

6061 requires various industrial structures with certain strength, high weldability and high corrosion resistance, such as pipes, rods, shaped materials, plate

6063 Industrial profiles, building profiles, irrigation pipes and extruded materials for vehicles, benches, furniture, fences, etc.

6066 Forgings and Welded Structural Extrusions

6070 Extruded materials and tubes for heavy duty welded structures and the automotive industry

6101 High-strength rods, electrical conductors and radiator materials for buses

6151 Die forging crankshaft parts, machine parts and production rolling rings, which are required to have good forgeability, high strength and good corrosion resistance

6201 High Strength Conductive Bars and Wires

6205 Thick Plate, Pedals and High Impact Extrusions

6262 Threaded high-stress parts requiring better corrosion resistance than 2011 and 2017 alloys

6351 Extruded structural parts of vehicles, pipelines for water, oil, etc.

6463 Architectural and various appliance profiles, and automotive trim parts with a bright surface after anodizing

6A02 Aircraft engine parts, forgings and die forgings with complex shapes

DONGHENG GROUP is a large-scale industrial and trade integration enterprise integrating R&D, production and sales. The company has more than 100 outstanding employees and is located in the beautiful Qingdao. Mainly engaged in the production and sales of aluminum sheets, foils and coils. The company's scale has been continuously expanded, and its sales network has covered more than 60 countries around the world. The company takes the initiative to undertake social responsibilities, and regards ecological environmental protection as the key task of development.

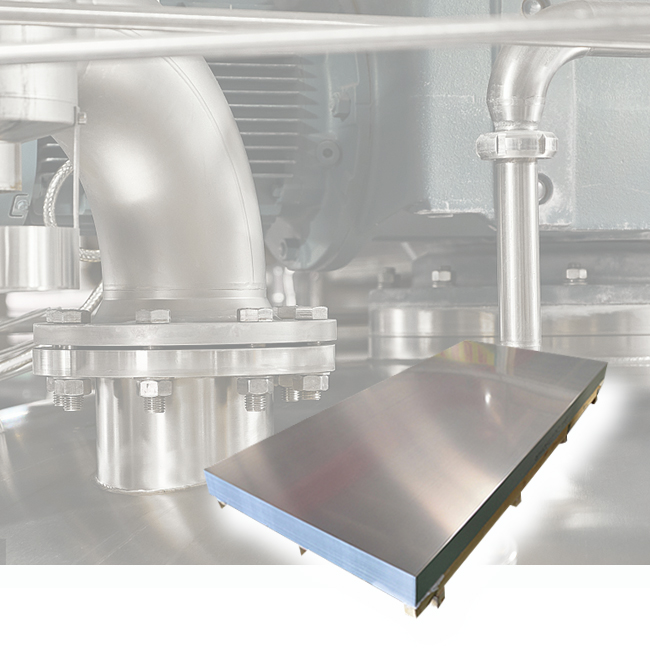

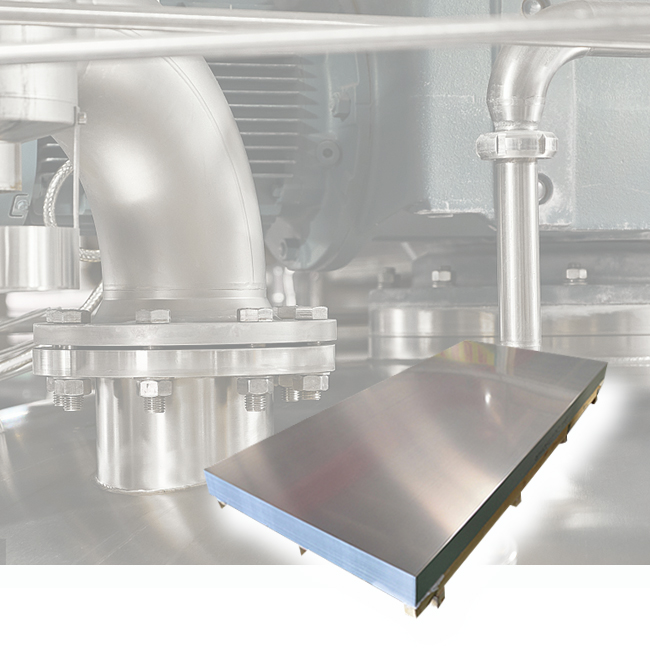

Various industrial structures with a certain strength, weldability and high corrosion resistance, such as automation equipment, medical equipment, military supplies, manufacturing trucks, tower buildings, ships, trams, furniture, mechanical parts, precision processing, etc.

Furnace Fixtures

manufacturing-trucks

ships

Private Plane

If you have any questions, please leave a message, we will reply as soon as possible

LET'S GET IN TOUCH AND COMMUNICATE!

We will contact you within 24 hours.